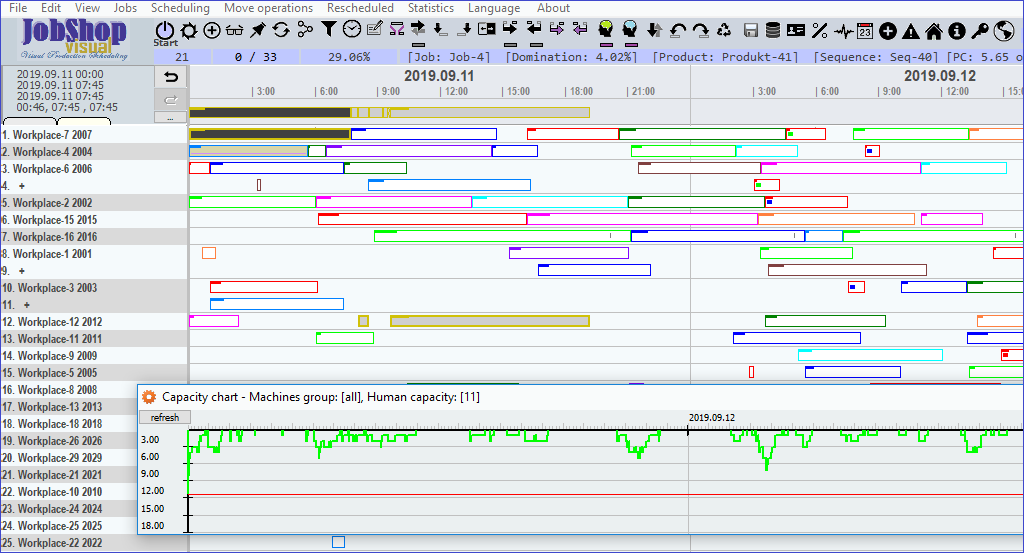

Job Shop Visual application allows visual production planning. Production planning for two levels, for machines and human capacity. Suitable for sequential, custom manufacturing for small and medium-sized businesses or plants.

Advantages over similar products:

1. Quickly put into production, usually only 1-2 weeks after the connector has been created.

2. Visual planning as needed, capacity utilization of machines and people (drag and drop), shift and holiday consideration.

3. Very low price, easy to use.

Video: Job Shop Visual, program options in English